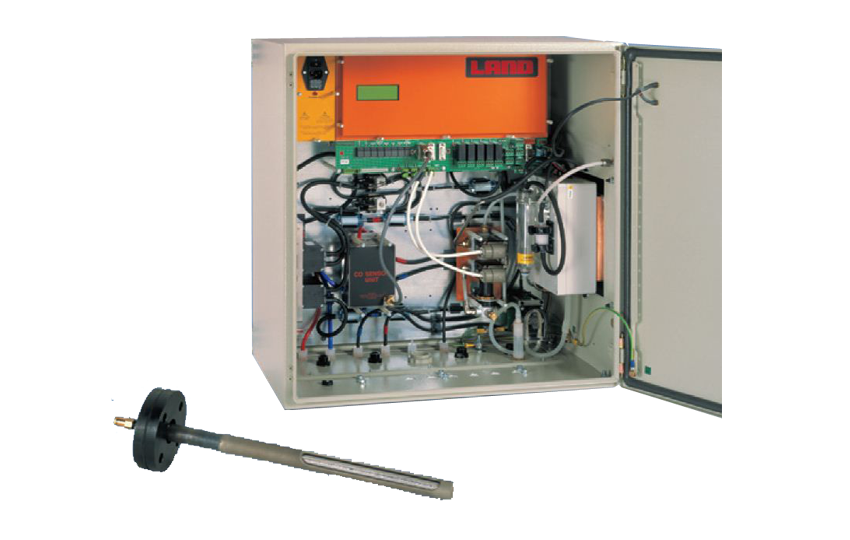

This unique detection system, is specifically designed to detect rapid build-up of carbon monoxide inside pulverizing coal mills. It continuously monitors the atmosphere inside the mill, and responds very quickly to any significant increase in the levels of CO, created by the onset of a mill fire. This provides the operator with advance warning to enable preventative action to be taken before damage to the plant, or injury to personnel occurs.

The transportation of coal by rail brings with it the potential risk of fire. Coal stored and moved in rail cars can provide the environment necessary for coal to smolder, which if undetected leads to fire.

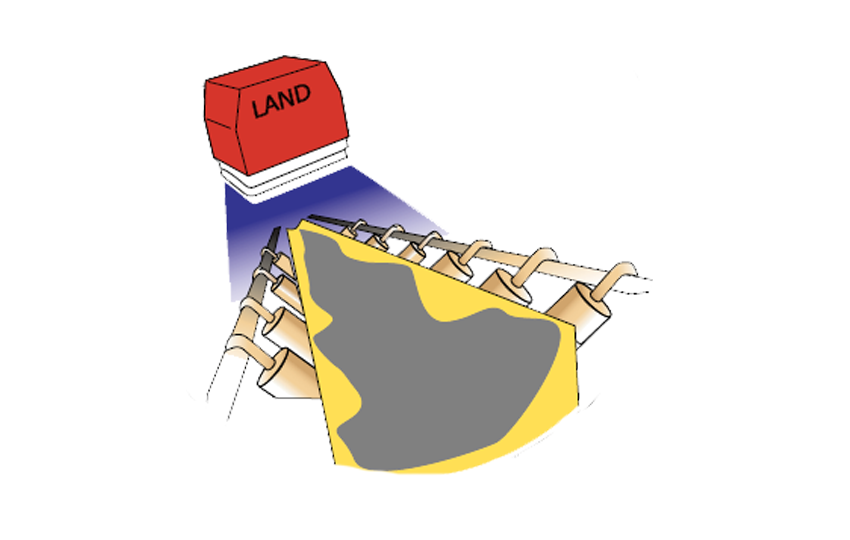

The Railcar Fire Detector scans coal as it is unloaded and drops from the railcar through under track grates into a storage hopper (track hopper). Any hotspots or smoldering coal is detected and fire prevention action can be taken.

The transportation of coal on any form of conveyor system has the potential to ignite, with the ultimate outcome being a fire. Coal (even in small amounts) is a very good insulator, so fire which is burning beneath the surface may not be immediately obvious. A single point temperature measurement system can detect a hot spot, but is just as often likely to miss one.

Storing coal in large piles has the inherent risk of spontaneous combustion. There are many industry guidelines to the best method for storing coal in piles. These guidelines include avoidance of spontaneous combustion with regard to pile angles, compression and surface smoothing. Even strict adherence to these guidelines (particularly with the more volatile coals) may in some circumstances not be enough. An early warning system to prevent the onset of fire remains the best and most reliable solution.